Well it’s Year Two of this homeschooling thing and I’m simultaneously more relaxed about the process, and more aware of how critical it is to use our time well. Homeschooling is extremely time efficient, particularly in the younger grades, but man, three months can slip by with very little forward progress if you aren’t careful.

My entire family got sick just as school started in early-September, and we are all just now more-or-less ok. Because of what I can only describe as a comedy of medical errors, three of the four of us are on a course of antibiotics at the moment, but everyone is finally back to good spirits and back to functional and non-contagious.

One of the great things about homeschooling is that the family can get sick and we can accommodate lower energy levels and multiple rounds of doctors appointments without concern that the truancy police are going to show up at our door. But it’s still important that the kids progress in their education.

Oliver is a first grader this year. Kindergarten to first grade is a big step for little feet. We feel it’s important to continue to push essential fundamentals (including the fundamental skill of being able to sit down and get work done for increasing lengths of time), while still allowing him lots of time to be a kid.

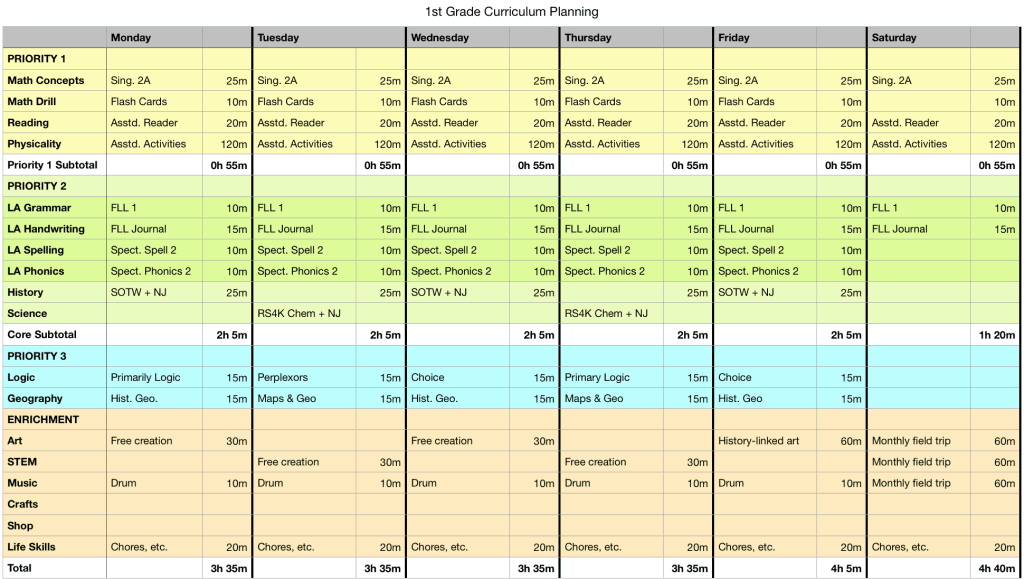

To get the right balance day-to-day, we handle his curriculum on a triage basis. Some stuff is absolutely non-negotiable, some is important, some we can let slide without too much worry, and some is either non-essential, or is mostly enrichment that just happens without too much planning on our part.

Here’s how that looks when I map out and organize his first grade education.

Priority 1 Topics: Non-Negotiable

In yellow, above. These are the things he has to do, more or less daily, come hell or high water. Priority 1 skills are fundamental to future competency in everything – not just academics, but basic life. We include math and reading in this category. These topics are covered nearly every day for about 20 to 30 minutes each.

For Oliver, I also include 2 hours of daily “Physicality” in this category although I don’t count those two hours as academic time. Basically, if he doesn’t run around, play hard, and have some outlet for his natural little-boy physical energy, he goes “trainwreck” pretty quickly and it’s hard to get him to sit and participate in the rest of his formal education.

Priority 2 Topics: Very Important

In green, above. These topics are important fundamentals, and we try to cover them two to five times a week. However, if a lesson is pushed back or the pacing needs to “breathe” to accommodate real life, that’s okay.

Priority 2 topics are Language Arts (slightly shaded green), which includes grammar, handwriting, spelling and phonics, History and formal Science. Let me briefly clarify that just wandering around, playing and being an observant kid is often foundational science. What I’m talking about here isn’t that. It’s a specific, formal effort to instill scientific concepts at an age-appropriate level.

Together, Priority 1 and Priority 2 subjects – math, reading, language arts, science and history – make up Oliver’s core 1st grade academic curriculum. Covering all of these subjects takes about 2 hours a day.

Priority 3 Topics: Nice To Have

In blue, above. I really like to include these topics because I think they are important, and Oliver generally thinks they are fun. But if we skip these topics for a week because we are all sick – meh, oh well. At this age, these topics aren’t critical building blocks of his learning like the Priority 1 and Priority 2 topics.

For first grade, we include geography and logic in this category.

Enrichment: It Mostly Just Happens

It’s not that I don’t consider these enrichment topics important – it’s more that Oliver will naturally self-lead into all these activities, so for his personality and age, trying to “formalize” these things too much would just backfire.

Enrichment activities include art, woodshop, cooking, life skills, music, primitive technology skills, crafts, gardening, small animal husbandry, fun STEM activities like lego or Minecraft, and about a zillion other things that just happen in the course of life.

I also file camping, travel, swimming with grandma, and periodic field trips to museums, maker and cultural fairs, the zoo, the aquarium, etc. under enrichment. Sure, we make it a priority to do or attend these things regularly, but if we push back a zoo trip for a week or five, or go to Brickcon instead of the art museum, it makes no long term difference to Oliver’s educational scaffolding.

What’s Missing?

I think one of the most important components of a smart early elementary education is learning a foreign language. Why? Because young brains learn language more easily and naturally, so it seems terribly silly not to take advantage of that and cram a second or third language in there while the timing is optimum.

But, for a variety of reasons, Oliver isn’t taking a foreign language at our homeschool campus and I haven’t found a learn-at-home option I like.

Maybe next semester. Or, if you have an at-home language learning program for the early elementary crowd that you love, please let me know! Bonus points for something online and game-based like DuoLingo, but without the reading requirement.

Curriculum Details

When you homeschool you become a curriculum nerd. It’s just inevitable. I like seeing what other homeschool parents are doing, so here’s the nitty gritty of what we are doing for first grade.

Some of the curriculum I’m currently using I adore with a passionate loyalty, and some would be replaced tomorrow if I could find anything better. Details below.

Math

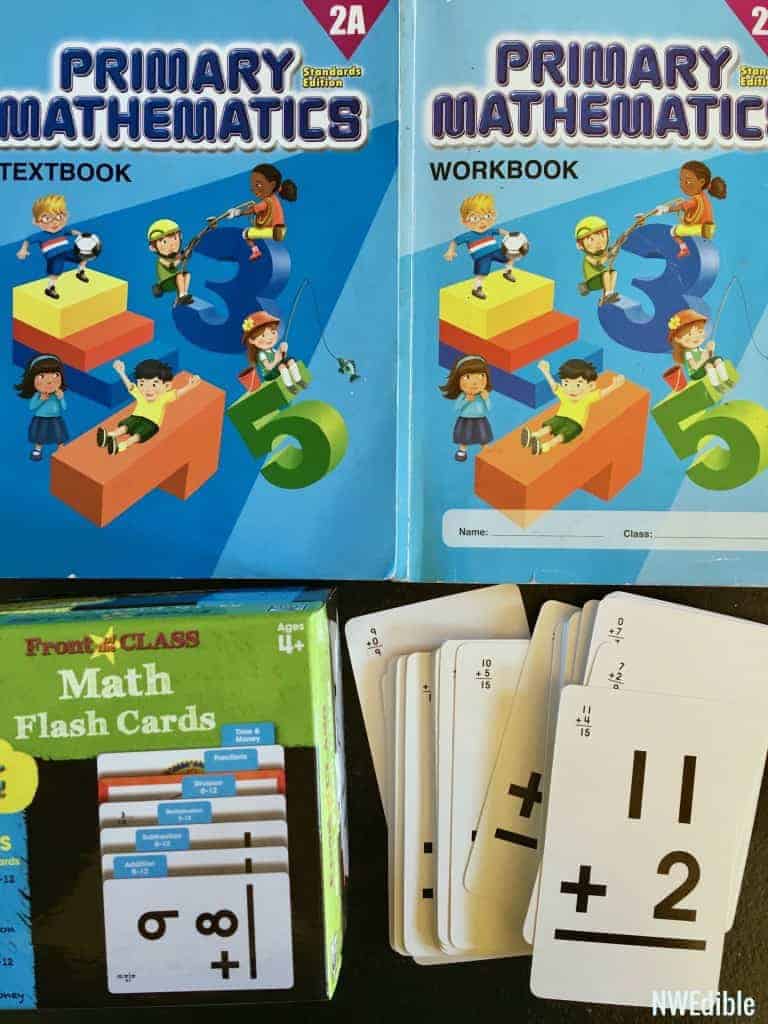

We use the “Singapore Math” program from Marshall Cavendish Education. Apparently it’s closely based off of how math is taught in Singapore. Singapore regularly kicks everyone’s butt in math so it’s fair to assume the Singapore-method of math instruction has something going for it.

This is the same program we used when Bella was homeschooled in Kindergarten, so I’m comfortable with it. It’s a strong curriculum for teaching math conceptually, but it doesn’t go so far into representational dots and squiggles that actual numbers and practice drills get ignored. It worked very well for Bella until she went off to public school, and Oliver is thriving with it now.

The Singapore Math system has three different variations of textbooks and workbooks (it was 2 versions back when I started homeschooling Bella.) The different editions are tweaked to meet different governmental standards. At some point I made the decision to go with the “Standards Edition” version of the program. I think when I researched it, the Standards Edition seemed more rigorous, and it included metric. But it’s been a long time and honestly I don’t remember exactly. We use the Standards edition and I love that for Oliver.

We supplement with frequent math memorization drills with addition and subtraction flashcards. I have a set of flashcards that includes a set of cards for all the basic arithmetic operations, but I honestly don’t think there is too much difference between one pack of flashcards and another.

Reading

When Bella was about Oliver’s age she was reading fluently from upper-elementary level chapter books. I never had to teach her to read, she just took to it like a fish to water. We’ve had to be much more systematic about teaching Oliver reading and language arts skills.

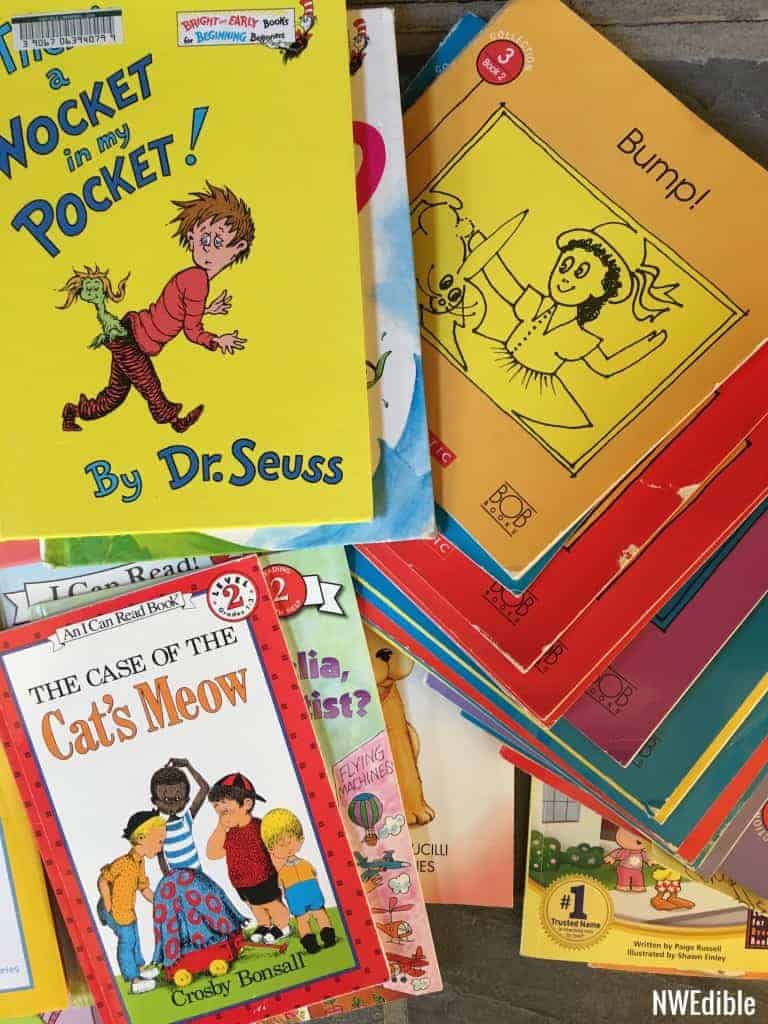

Last year we used the very excellent Bob Books to introduce reading skills methodically. We had some rough patches at the beginning but Oliver’s reading ability jumped incredibly through this process. Unfortunately, we’ve now read all the Bob Books. We’re currently practicing daily reading with Dr. Seuss books and leveled readers from the library, but Oliver benefited more from the methodical, slow-but-steady complexity increases in the Bob Books.

If anyone knows of something that picks up where the Bob Books leave off, I’d love to hear about it.

Language Arts

Grammar

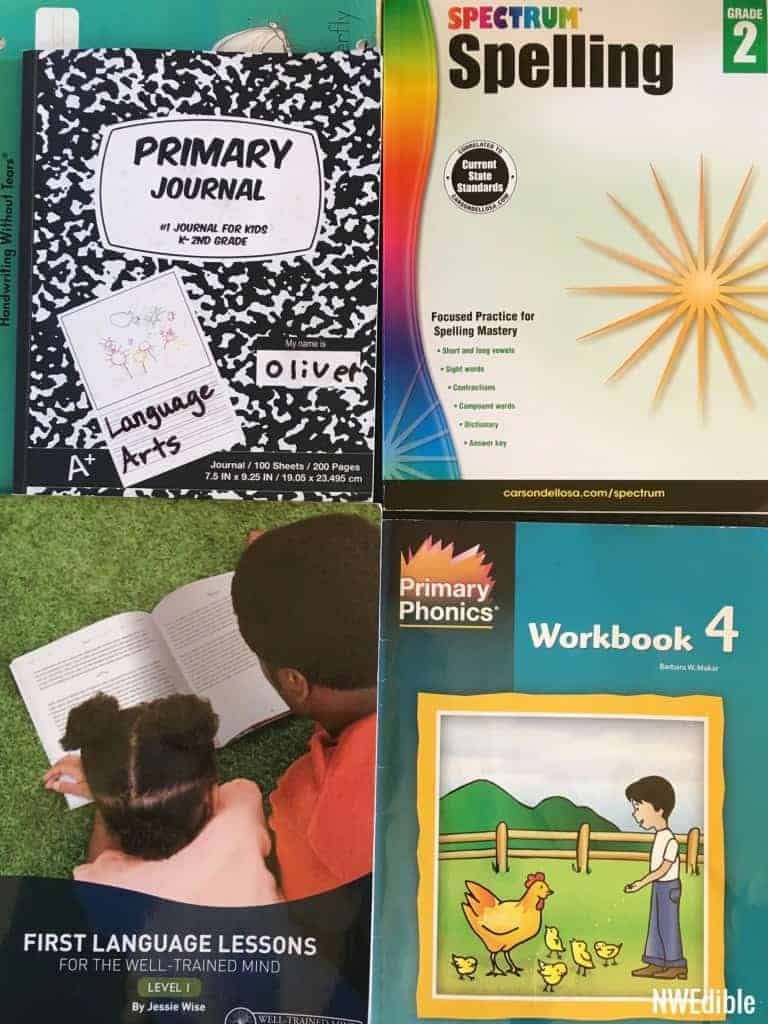

We began First Language Lessons Level 1 this year. It’s a bit slow moving for an older first grader, so I often combine two or more lessons into one. Other than that, it’s an easy-to-use curriculum that provides grammar and language arts basics in the best format I’ve yet seen. As long as I keep it moving, Oliver loves it. We will definitely continue with this program.

Handwriting

Oliver started Handwriting without Tears last year. It’s is a solid writing program and was probably the best choice for Oliver for basic letter formation.

However, I taught Bella to write without buying a single workbook using the D’Nealian system and far prefer the resultant D’Nealian script to the Handwriting without Tears block letters. If you intend for your child to learn cursive (it’s quite a quaint little skill these days) I think D’Nealian or a similar script sets a child up for an easier time with cursive later on.

In any event, Oliver is 100% over the idea of specific handwriting practice, so we’ve moved on to copywork. He has a composition book and copies one to three sentences from or inspired by the First Language Lessons lesson of the day. Then he draws a small picture to go along with his copywork.

Spelling

At this age, it seems like so much blurs together. If Oliver’s copywork contains a spelling mistake, I point it out and he fixes it. But in my daughter’s otherwise excellent writing (she’s in 8th grade now) I see the consequences of an early elementary education that never taught spelling as a specific, sequential skill, and I’m fairly determined that my son not have those same gaps.

We’ve just started with the Spectrum Spelling workbook and I really like it. We started with the Grade 2 book because that seemed appropriate for Oliver’s phonics and sound-it-out ability. Even a grade up, it’s none to challenging. Choose based on photos of the actual worksheets, or flip through the book.

In Kindergarten with my daughter we used Spelling Workout, which was a bit more rigorous as I recall, but also pretty boring. The Spectrum book is a good fit so far for Oliver. I’m happy with it.

Phonics

Oliver started Primary Phonics back in his pre-K Montessori school. Although the workbooks themselves are fairly cheap (both in cost and production quality), I would absolutely recommend them if you don’t quite know how to teach your child phonics. They are basic, effective, self-explanatory and easy to use.

Unfortunately, Oliver is super bored with the entire series. He’s been doing these same style workbooks for 3+ years. Because the Spectrum spelling program has been well-received, we are going to try the the Spectrum phonics book too.

History

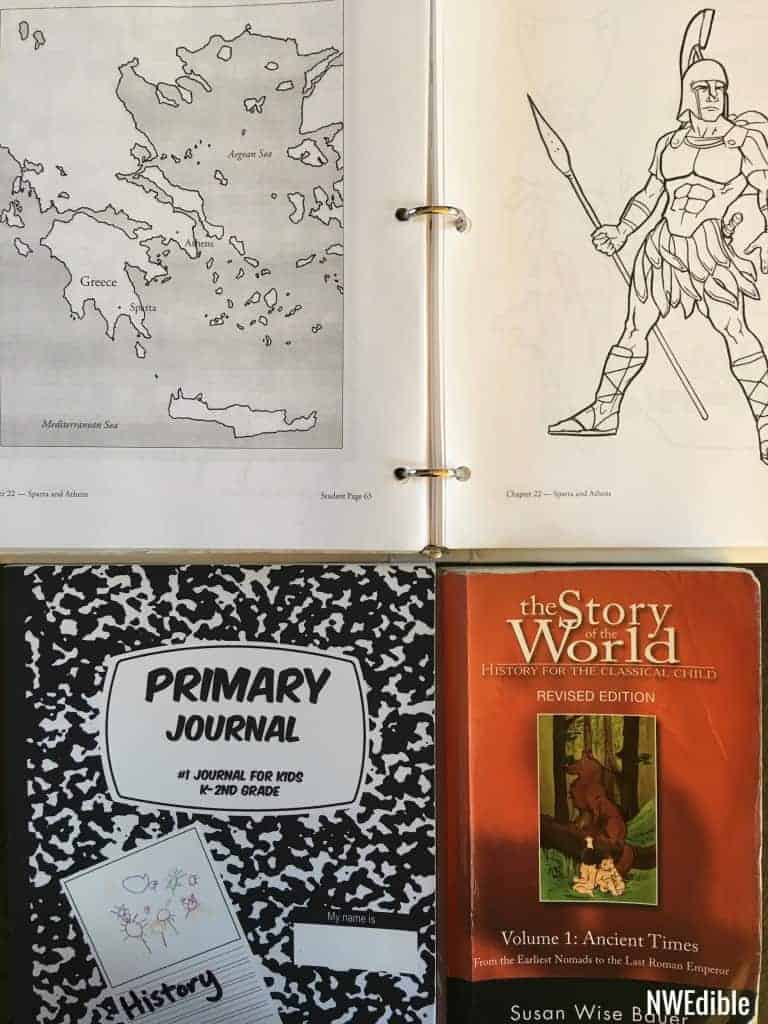

We follow a homeschooling philosophy dubbed “Classical.” I could probably write a whole post about why we are classical-ish in our homeschooling, but for those of you who don’t homeschool, the study of history is pretty important in a classical education. There’s a lot of reasoning behind this, but the short version is – if you don’t know where you’ve been, you can’t possibly have a clue where you are going.

Like many classical homeschoolers, we study history as a narrative story, and use a book series called The Story of the World. This is a breezy, early-elementary appropriate four-part series that breaks world history down into Ancient Times, Middle Ages, Early Modern, and Modern times.

I love the Story of The World narrative spine framework for teaching history. I read a chapter at a time to Oliver, and then he narrates back to me what he learned. I write what he says down in a composition book and then he draws a little picture to illustrate the lesson. We reinforce the lesson with additional reading, or bedtime listening of related audiobooks as Oliver falls asleep.

Science

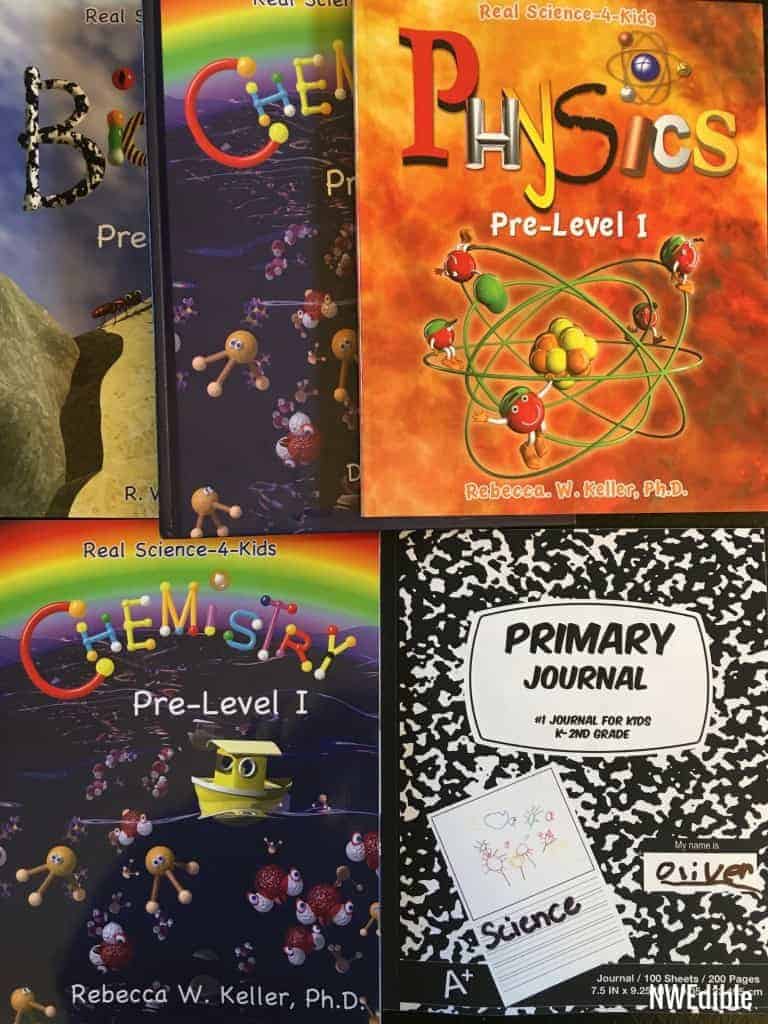

The best secular science curriculum I’ve seen for pre-kindergarten through very early elementary age is the Real Science 4 Kids series. These are adorable foundational texts in astronomy, biology, chemistry, geology and physics.

I expect Oliver to work through the three “pre-level” books we have in biology, chemistry and physics this year, possibly into next year. We’ll likely continue on with the elementary level books from this same series to cover astronomy, biology, chemistry, geology and physics in 2nd and 3rd grade.

Somewhere around 4th or 5th grade, I’d expect him to have worked firmly into the content in the “middle school” marketed books. At that point, we will reassess our science curriculum. These books are scientifically accurate but cartoonish in their formatting and don’t go into great depth. That’s an asset in the early to middle elementary years, but would seem babyish to older kids I think. I certainly would not use this series as a science spine for my actual 8th grade (middle school) kid.

Logic

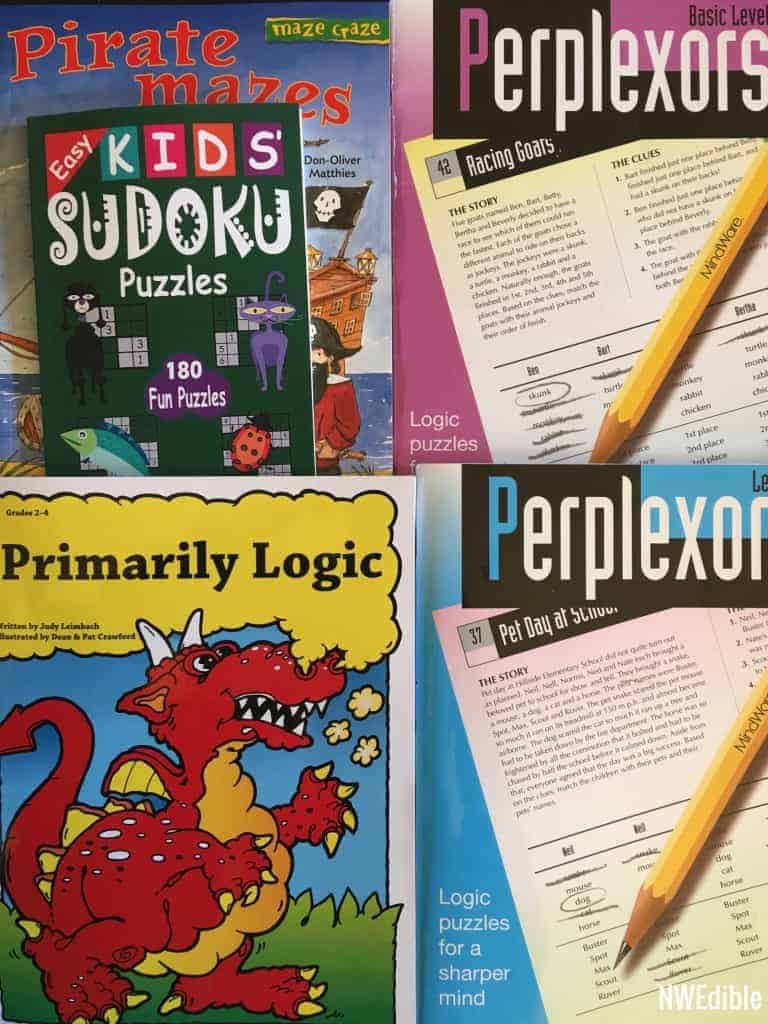

At this age, logic is more game play centered around deduction and puzzle solving. Oliver and I are both huge fans of matrix logic style puzzles. The best presentation of this kind of logic puzzle I’ve seen is the Perplexors series. Oliver can handle the Basic Level puzzles on his own quite well. Level A puzzles usually require a hint or guidance from mom.

For this school year we added the Primarily Logic workbook. We both love it.

We supplement with additional logic, fun puzzle solving and critical thinking support activities like SET, mazes, and Sudoku.

Geography

I’ve had a difficult time finding a geography curriculum I really love for either of my kids. We study geography in a historical context along with history, so Oliver, for example, knows that the Nile is an important river that allowed for the flourishing of the Ancient Egyptian civilization.

But you need basic “how many oceans are there?” and “find Brazil on the globe” type geography, too, if you want to have a basic grasp of what’s going on in the world around you. I’m still looking for an ideal way to teach this kind of basic geography to my children.

Right now Oliver is doing a workbook called The Complete Book of Maps and Geography. It claims to be for grades 3rd to 6th, but the book starts off with very simple concepts, and Oliver isn’t having trouble with the early lessons we’ve tackled.

What I like: easy for me. Hey, it’s a workbook. I explain/ask, he answers/completes. It is well organized. The sections are methodical and I think the workbook will build nicely on prior lessons. What I don’t like: there is very little focus on world geography. This workbook is very USA-centric. In my educational philosophy, geography is important because it helps you contextualize historical and current events, and this has limited utility toward that goal.

For now, I’ll pick and choose the lessons I want from the book, but I’m not done looking for a geography solution.

Enrichment

One of the few consistently planned enrichment activities is a near-weekly art project on Friday that ties in with our history lessons. Last week, for example, the kids made bull-jumping frescos after studying the Minoan civilization.

Here’s a few resources I like for inspiring activities like this and a more “living history” approach in the elementary years:

- Ancient Egyptians and Their Neighbors: An Activity Guide

- Ancient Israelites and Their Neighbors: An Activity Guide

- The Dover History Series of Coloring Books

- Tools of the Ancient Greeks: A Kid’s Guide to the History and Science of Life in Ancient Greece – this one is written by Kris Bordessa who you may know as the lovely, talented and inspirational blogger behind Attainable Sustainable!

Gosh!! You make it sound so appealing, I want to check out some of those texts … for me! Really makes me wish I had done this with my kids…. even if only sneaking ‘enrichment’ into a public school education (which typically can use it!) And I suspect a lot of other parents are going to have to try this out… good on ya 😉

Of course, along with the warm doing-it-together benefits, there’s probably also the ‘gee, I have ‘this or that’ to get done, and this is pretty boring!’ moments. But, just another delightful challenge for you to figure out an improvement.

You do have a gift (as do we all, of course 🙂 …. but you are so happy to share! Thanks…..

The best part of being a homeschool parent, after time with kids, is getting to be a student too! 🙂 Thank you for your kind words!

Nancy,

One of the leaders in the classical home-school movement wrote a book for adults to help them fill in the gaps, and work toward those enrichment goals. It’s called the Well-Educated Mind: A Guide to the Classical Education You Never Had by Susan Wise Bauer. I’ve been using her classical model as guide for our homeschooling, and bought the book so I can continue on when we are finished.

And just like that I bought Chemistry-Astronomy-Biology pre-level! Woot, thanks for that! (Doing first grade casually here since my daughter is K-age). I’m jealous of your campus. Here (in Quebec) there is no such thing. We do have a bilingual (French0English) household, though, so that’s already a given for us (yeah but I want to learn Spanish! And Esperanto! And do Latin like I did! hmm, full disclaimer, I’m a translator. So languages? Yes please! And books? I’m easily swayed!)

🙂

The pre-level is perfect for kindergarten/first. Skip the lab and workbooks and just read the chapters with your daughter while snuggling. It’s the best. 🙂 I have Oliver “narrate back” what he learned and I write down what he said in his little science composition book.

Oh, also! One of the great things about the campus is a full, four-year latin program. Bella adores it! She thinks Latin is the best!

Jealousy went up a notch! But I’m glad someone somewhere offers it still — schools here no longer do, not even my old private high school.

Hey Erica!

This is fantastic! I have been looking for the best work book type activities for the kids I nanny! Awesome!

Also, about the geography, when I was in middle school we used a program called Sheppard Software. It has world geography puzzle/games. By the time I got to high school I had Africa, Asia, and European countries and capitals memorized. I still have a decent handle on the countries today! Here is the link:

http://www.sheppardsoftware.com/Geography.htm

That is such a great suggestion – thank you thank you!!! I followed your link, and ended up finding a similar online geography game site and then the kids sat down and stole my computer and voluntarily did Geography for 45 minutes each. Problem solved! Great suggestion!

Haha! Great! Sometimes I still pop on over and fiddle around with it for a bit too! Glad it worked for you all!

My son learned to read like your daughter–a bit of osmosis–but I did try to stock his shelf with a sequence of books he could read on his own. There was some Bob. The Scholastic book flyers (or scholastic.com) helped a lot with ideas for leveled reading. We got good mileage from their collection Sight Word Tales (just for pleasure reading, we ignored its teaching guide) and from their nonfiction offerings, like the leveled National Geographic booklets.

Great tip, thank you so much! I love the idea of the National Geographic books especially because Oliver is a little more drawn to non-fiction. I’m looking at Sight Word Tales now…I think I’ll see if my library system carries it. Thank you for the specific recommendations.

You’re welcome. Just thinking–I also really liked the DK readers for my son. https://www.dk.com/us/learn-to-read/ Our library had more of the comic-based ones, but there’s some good nonfiction.

FWIW, my sister and I were homeschooled through 8th grade with basically the same curriculum in early elementary, including dedicated spelling books, and she is a terrible speller while I am an excellent one (it’s kind of a family joke, actually). My mom always assumed it was because I’ve been a voracious reader since I was very young, while my sister was much less so, but if Bella is both a voracious reader and a not-so-great speller, this blows our theory out of the water!

I know this post was focused on first grade level but your daughter is the perfect age for Mathcounts! Mathcounts is a national middle school mathematics competition (5-8th grade). Your homeschool group could easily set up a team or just use some of their resources for fun and interesting problems. I’m a proud mathcouths alum and past volunteer (hmm maybe should be present volunteer- I’ll look into that) Lots of fond memories! https://www.mathcounts.org/

For geography have you even played GeoGuessr? https://geoguessr.com/ It uses the google street view imagery and you have to guess where on the planet you are. I’m hooked! You can use it at as starting point for all sorts of conversations, are the cars driving on the right or left? Where are there desserts? what places have palm trees? etc etc.

Excited to try GeoGuessr–thanks!

Love this post. Thanks for taking the time to share what you use. Could I tangent off your post and ask for some advice? My 5yo preschooler is obsessed with electricity and all things mechanical (that involve electricity!). His favorite toys are string lights and SnapCircuits kits. Here is a sampling of questions I hear on a regular basis: How does the car engine charge? How does an elevator work? Does this have a fuse in it? I’d love to find some books and/or videos that do a good job explaining electricity and electrical appliances to someone his age. “Thing Explainer” is fantastic – except it really should reference the actual terms too as he wants to know what everything is called and half the time I have no idea myself! Any ideas?

When I was a kid, we loved reading “The Way Things Work” (the oldest version). I don’t know if that would be quite what you’re looking for, but the pictures really helped bring concepts alive for me and the mammoths are cute! https://www.amazon.com/Way-Things-Work-Now/dp/0544824385/ref=pd_cp_14_3?_encoding=UTF8&pd_rd_i=0544824385&pd_rd_r=DABPK45EXG4RYGN4D97P&pd_rd_w=ge96b&pd_rd_wg=pU2eN&psc=1&refRID=DABPK45EXG4RYGN4D97P

Bethant, thank you! We’ve borrowed it from the library and it’s brilliant!

These may not directly answer your son’s questions, but here are some resources we enjoyed. (My son was just like him, Snap Circuits into LEGO mindstorm now.) The Kid Should See This blog, Physics Girl’s YouTube channel, LEGO education sets (it’s a different website, the geared sets are terrific), Squishy Circuits (website), and the ScienceWiz Inventions kit by Penny Norman. The bigger K’nex sets with motors are also fun (but inventory the parts before you start building, just in case).

Wynne, these are exactly what I’m looking for. He’s watched about 20 of the videos on the The Kid Should See This site already! At a science carnival we recently attended, the library exhibited several of the Squishy Circuits, which he loved; I didn’t realize they had a website! And the Physics Girl and LEGO Ed sites are marvelous. So thankful for social media crowdsourcing! THANK YOU.

Wow! You’re ambitious. As an unschooling mom, I’m feeling embarrassingly lazy after looking at that chart. Fortunately, my 12 year old has learned a reasonable amount (or more) of most of these subjects while just following her interests, though she’s been slacking on math the last few years and wants to buckle down to catch up to grade level. I may try to make a math semi-schedule for the younger one at some point…

Hello!

I imagine you know this already, but just in case you don’t, we love Michael Clay Thompson’s Language Art series (available through Royal Fireworks). My children love it. I love it and I think it makes grammar and language approachable without resorting to cute. I use Singapore Math too (I actually like the common core version), and I’ve added Beast Academy to the mix (my daughter is grade 5). Singapore Math focuses on “real world math.” Beast Academy is more – how should I say – “pure math.” It introduces a lot of challenging concepts early. This might be problematic except that the material is presented in a very ingenious and engaging way – well done comics with good dialogue. My children read it over and over just for fun (perhaps this is a reflection of the kind of kids my children are and not the books, but I know lots of children who find it engaging).

Jackie Kim

Thank you for posting this! I googled “first grade daily schedule” and your post popped up. This fits our family perfectly as we like to include a lot more “home economics” in our schedule like you (baking, gardening, sewing, camping, etc). I love your breakdown of each category and how you’ve color coded your schedule; that way you (or I) won’t feel guilty if you don’t get to some of those lesser important tasks every day.

The rest of your site is beautiful and inspiring as well. As a former (and hopeful future) resident of the PNW, I long for the days of rain and beautiful greenery. You have a new follower.